Testing is definitely easier when you can compare all the numbers. Get one of Bruce's DM's by the sound of it or stick to water. I have played a bit with the PTS and I wouldn't bother with anything else.

Definitely limit the pressure if the construction isn't 100%, you need those jewels.

A washer held down by a spring would work and easy to adjust

Jim

Not the Mercdog again

-

RACEPUMPER

- Posts: 447

- Joined: Wed Aug 25, 2010 7:54 am

- Location: Riverina Australia

Re: Not the Mercdog again

I really love making stuff but don't finish much

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

The construction is ok it's the stupid MSD control valve design - they practically have no control with small flows -. They are too big in diameter, so they have a very large force on them, and coupled to them being so flexible, they stick to the seat in int, or are pushed open in exh, making the pressure creep up when you're not looking - hence the blown port lid -.RACEPUMPER wrote: Definitely limit the pressure if the construction isn't 100%, you need those jewels.

These faulty FP1s are a problem because there is no way I can afford another DM of any brand, and I'm not sure the owner of the MSD will be keen with his either, and going back to water manometers will mean that I will need to put the orifice wheel back.

What a depressing headache.

-

RACEPUMPER

- Posts: 447

- Joined: Wed Aug 25, 2010 7:54 am

- Location: Riverina Australia

Re: Not the Mercdog again

Well ultimately it's up to you and the bench owner to decide what happens, if he wants a bench that works your options are pretty slim. Have you priced one of Bruce's DM's? They are not ridiculous and it would make the bench work as good as it looks. There's no cheaper way to do it apart from water gauges and if you put that leaking rotating orifice back in you would regret it forever.

Jim

Jim

I really love making stuff but don't finish much

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

The owner isn't going to use this bench for porting, but more as a sales tool and for people that just want a flow test - hence why it has to look pretty -. I wasn't keen of using the FP1 that came with the bench because the software doesn't make pretty enough reports for the owners taste. And the thought of making a pretty spreadsheet to go with it was just another thing I'm not getting paid for.

Currently I'm going to fudge the cds - I'm currently using 0.33 on a 2.45" 3mm square edge orifice for the intake - and see what happens with the 3 PAPs. I will look at the PTS, but if it doesn't have a pretty report with graphs the owner will probably go with Performance Trends and PFA - he likes the look of it.

I fixed most of the control valve issues by sandwiching the the flexible bowl bottoms between 2 metal disks, but really the valve should be smaller, and the rod should be longer and supported by a bridge on the motor side. Or even better, copy the complete smaller SF design on an Alum base plate, and bolt it down over the current hole.

Currently I'm going to fudge the cds - I'm currently using 0.33 on a 2.45" 3mm square edge orifice for the intake - and see what happens with the 3 PAPs. I will look at the PTS, but if it doesn't have a pretty report with graphs the owner will probably go with Performance Trends and PFA - he likes the look of it.

I fixed most of the control valve issues by sandwiching the the flexible bowl bottoms between 2 metal disks, but really the valve should be smaller, and the rod should be longer and supported by a bridge on the motor side. Or even better, copy the complete smaller SF design on an Alum base plate, and bolt it down over the current hole.

-

1960FL

- Posts: 1338

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: Not the Mercdog again

Not ture, do your homework and read the forum. the beauty of the PTS DM is you can have anything you want as the data is outout in a CSV file.the PTS, but if it doesn't have a pretty report with graphs

Look at the attacehd FREE spreadsheet we put up as an open source project for managing DATA.

This was not in the open area but i realy do not care, as it is open source the code is nothing special and it is here to promote a group effort to support DM output data in a way that is not bound by my programming within FlowSoft

Rick

You do not have the required permissions to view the files attached to this post.

-

1960FL

- Posts: 1338

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: Not the Mercdog again

If you want to try and play with this sheet here are a couple of test data files that are output from FlowSoft.

Please remember this sheet was an example of what we could do as a group and was designed to give the small guy something to build off of to work with individuals (Customers) and have a more professional looking output than some numbers on paper, this is just a foundation and ideas.

Rick

Please remember this sheet was an example of what we could do as a group and was designed to give the small guy something to build off of to work with individuals (Customers) and have a more professional looking output than some numbers on paper, this is just a foundation and ideas.

Rick

You do not have the required permissions to view the files attached to this post.

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

After 5 days of struggling with a high reading I came to the conclusion the FP1 was screwed, so I started looking for a new DMs. Unfortunately I found the leak - don't use cable ties for hose clamps - so now I'm back to writing something for the FP1.

When I get time I will look at sheets you have for the PTS, as I have some questions, and maybe even put my 2 cents worth into the pot.

I will post some other MSD mods, in-case anyone wants to use them.

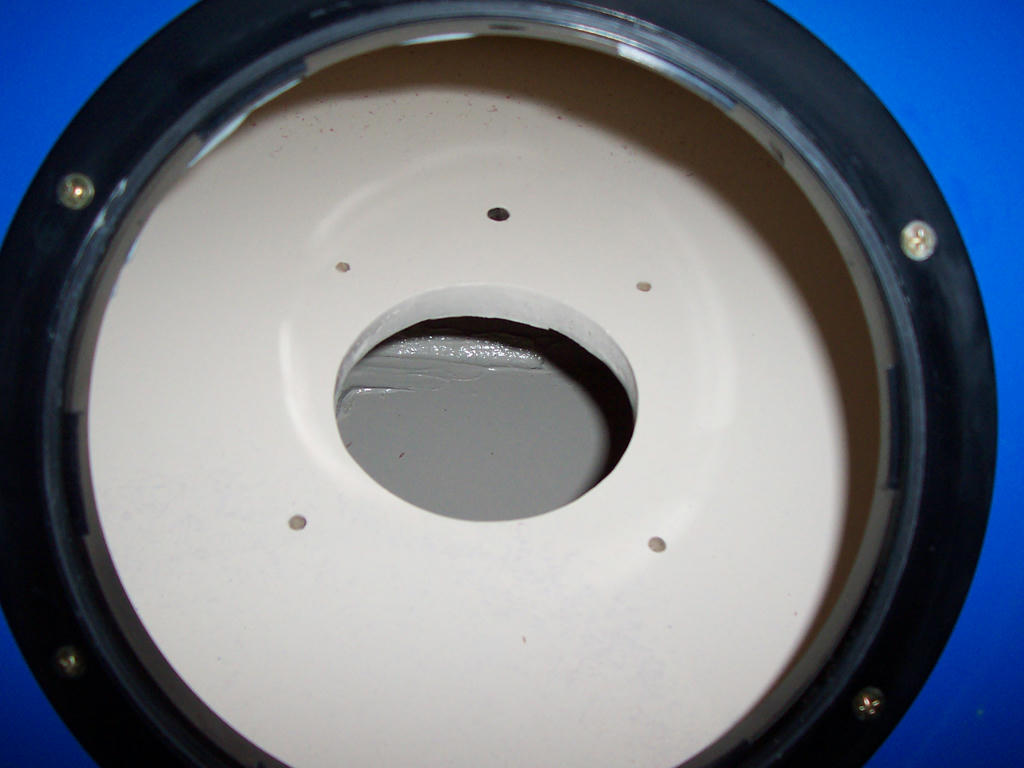

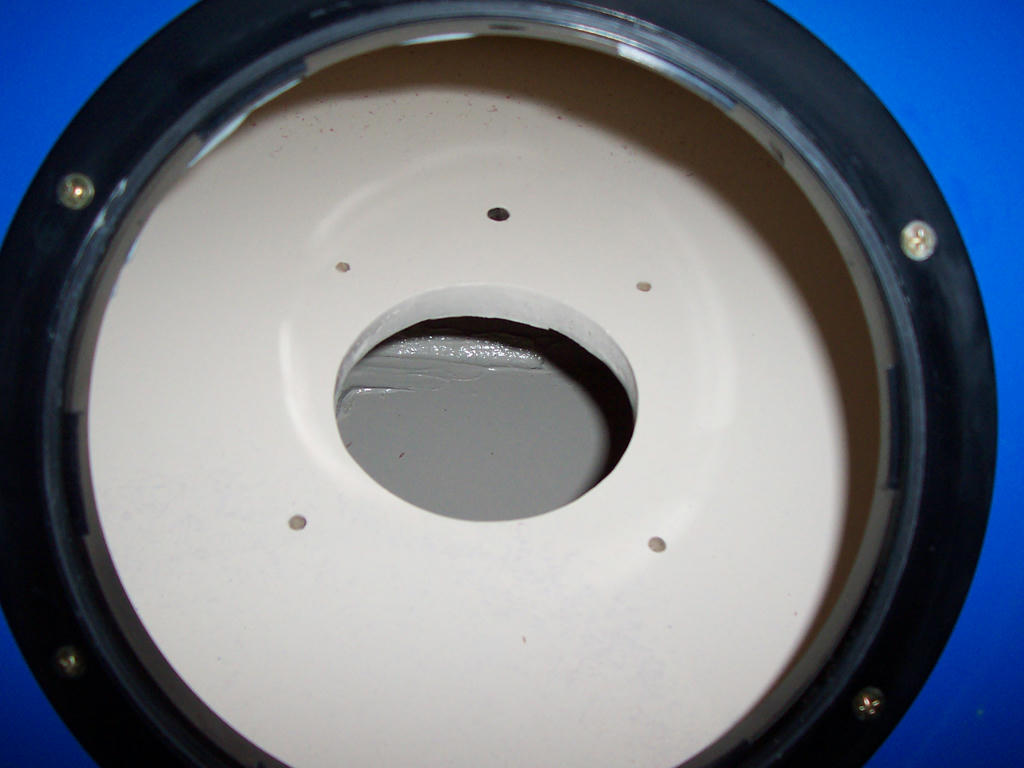

This is my internal orifice deflector board that gets around the 4" extended top settling chamber.

This is the plugged pie hole with a new round hole, and it's new position below the old orifice disk centre shaft hole - my pie hole was down there already because the original builder put the orifice board in up side down -.

When I get time I will look at sheets you have for the PTS, as I have some questions, and maybe even put my 2 cents worth into the pot.

I will post some other MSD mods, in-case anyone wants to use them.

This is my internal orifice deflector board that gets around the 4" extended top settling chamber.

This is the plugged pie hole with a new round hole, and it's new position below the old orifice disk centre shaft hole - my pie hole was down there already because the original builder put the orifice board in up side down -.

-

larrycavan

- Posts: 235

- Joined: Tue Mar 09, 2010 9:46 pm

Re: Not the Mercdog again

I'm amazed that you're still struggling with that bench..... I NEVER had all those issues with mine. Never had issues with the FP1 either. It's good unit. Several of us used them for a few years and it worked great. I sold mine to a guy in Michigan and he's been using it for a couple of years without issues as well....

When I got the PTS box to replace the FP1, I swapped it out, got out my calibration plates and in less than 30 minutes I was right back in business. BOTH the FP and PTS boxes worked without headaches in setup. BOTH were repeatable....

I had to run a lower coefficient for the orifice with the PTS box because I found it read high compared to the FP1 on my bench but that wasn't a problem.

The FP1 requires a broker application as the go between for your own programs. That is the only drawback I found but that really wasn't that much of an issue...... As far as cost goes the PTS box wins but honestly, if you know what you're doing and realize that matching every bench out there is a battle you will never win..... either will suffice.

Don't know that it matters all that much but I have my flow control valves the other way around. I figured out early on to install support plates where it attaches to the rod. I feel facing the opposite direction than what yours are creates a less turbulent environment in the lower chamber.

When I got the PTS box to replace the FP1, I swapped it out, got out my calibration plates and in less than 30 minutes I was right back in business. BOTH the FP and PTS boxes worked without headaches in setup. BOTH were repeatable....

I had to run a lower coefficient for the orifice with the PTS box because I found it read high compared to the FP1 on my bench but that wasn't a problem.

The FP1 requires a broker application as the go between for your own programs. That is the only drawback I found but that really wasn't that much of an issue...... As far as cost goes the PTS box wins but honestly, if you know what you're doing and realize that matching every bench out there is a battle you will never win..... either will suffice.

Don't know that it matters all that much but I have my flow control valves the other way around. I figured out early on to install support plates where it attaches to the rod. I feel facing the opposite direction than what yours are creates a less turbulent environment in the lower chamber.

Larry C

http://www.cavanaughracing.com

http://www.cavanaughracing.com

-

1960FL

- Posts: 1338

- Joined: Fri Jan 08, 2010 10:36 pm

- Location: Maryland

Re: Not the Mercdog again

Gray,After 5 days of struggling with a high reading I came to the conclusion the FP1 was screwed, so I started looking for a new DMs. Unfortunately I found the leak - don't use cable ties for hose clamps - so now I'm back to writing something for the FP1.

I would suggest you purchase FP Excel instead of chasing your tail writing from scratch besides if you have any Excel knowledge it will be a foundation to learn from. I am sure Larry would work with you to add the features you are looking for or maybe the insight as to how to get there.

Rick

-

Old Grey

- Posts: 216

- Joined: Sat Sep 18, 2010 9:38 pm

- Location: Sydney, Australia

Re: Not the Mercdog again

The leak in the FP1 tube was a simple fix, finding it wasn't. I assumed that the previously cable-tied tube on the FP1 was 100% solid, but somehow the previous builder got that wrong as well because it leaked under the knuckle of the cable tie - hence 5 days chasing other obvious areas first -.

I did find an old FP1 sheet someone had done around 2007, so I modified that already - hence another 5 days -, but it's other problems that I'm trying to compensate for that have converted the sheet from simple writing, to complex programming - I was going to buy Larry's sheet for the owner but it way too hard core for this novice -

Currently at this point in time I would have to say that this 2006 FP1, on this bench, with a single orifice, is a fail.

Problem A is that the FP1 can't read small flows when there is small pressure differentials over the internal orifice.

The first thing I did was ask the board how people are testing leakage with a single large orifice when there is nearly no pressure differential across the orifice, and the conclusion was that the PTS DM does it fine. Unfortunately after testing the FP1, it looks like it can't do it. The test I did was slowing closing a 1.94" valve to see the lowest reading I could get using a 2.54"(0-350cfm) single orifice with the FP1, and it would occasionally see 2.6cfm before it went straight to 0 cfm. 2.6cfm is a lot to leave unaccounted for in leakage, so to solve that I either need an orifice disk, or a more sensitive DM - I asked this question in an attempt at trying to get proof that the PTS DM would solve the problem if I bought one -.

http://www.flowbenchtech.com/forum/view ... f=5&t=1013

Problem B is that the bench doesn't seam to repeat, at least not as good as SF's 1 cfm.

3 tests using the FP1 set to sample #2 - it goes from 0-20 -, which provides good control of the bench because the FP1 responds quickly, there was a difference of 1.6cfm at 0.700" lift. 3 tests using the FP1 set to sample #5, which provides bad control of the bench because the FP1 responds so slowly that it's hard to set 28" at low flows, there was a difference of 1.3cfm at 0.700" lift. My solution was to add averaging to the Excel sheet so that I can use the fast response sample #2 and get more repeatability, but after posting the below question it looks like I'm not good enough to do array averaging, so I might see if I can add something simpler.

http://www.flowbenchtech.com/forum/view ... f=6&t=1011

Currently the owner is machining up new flow control valves - modification # 4 -, and I'm making acrylic vertical fluid manometers - he likes fancy looking stuff -.

I did find an old FP1 sheet someone had done around 2007, so I modified that already - hence another 5 days -, but it's other problems that I'm trying to compensate for that have converted the sheet from simple writing, to complex programming - I was going to buy Larry's sheet for the owner but it way too hard core for this novice -

Currently at this point in time I would have to say that this 2006 FP1, on this bench, with a single orifice, is a fail.

Problem A is that the FP1 can't read small flows when there is small pressure differentials over the internal orifice.

The first thing I did was ask the board how people are testing leakage with a single large orifice when there is nearly no pressure differential across the orifice, and the conclusion was that the PTS DM does it fine. Unfortunately after testing the FP1, it looks like it can't do it. The test I did was slowing closing a 1.94" valve to see the lowest reading I could get using a 2.54"(0-350cfm) single orifice with the FP1, and it would occasionally see 2.6cfm before it went straight to 0 cfm. 2.6cfm is a lot to leave unaccounted for in leakage, so to solve that I either need an orifice disk, or a more sensitive DM - I asked this question in an attempt at trying to get proof that the PTS DM would solve the problem if I bought one -.

http://www.flowbenchtech.com/forum/view ... f=5&t=1013

Problem B is that the bench doesn't seam to repeat, at least not as good as SF's 1 cfm.

3 tests using the FP1 set to sample #2 - it goes from 0-20 -, which provides good control of the bench because the FP1 responds quickly, there was a difference of 1.6cfm at 0.700" lift. 3 tests using the FP1 set to sample #5, which provides bad control of the bench because the FP1 responds so slowly that it's hard to set 28" at low flows, there was a difference of 1.3cfm at 0.700" lift. My solution was to add averaging to the Excel sheet so that I can use the fast response sample #2 and get more repeatability, but after posting the below question it looks like I'm not good enough to do array averaging, so I might see if I can add something simpler.

http://www.flowbenchtech.com/forum/view ... f=6&t=1011

Currently the owner is machining up new flow control valves - modification # 4 -, and I'm making acrylic vertical fluid manometers - he likes fancy looking stuff -.