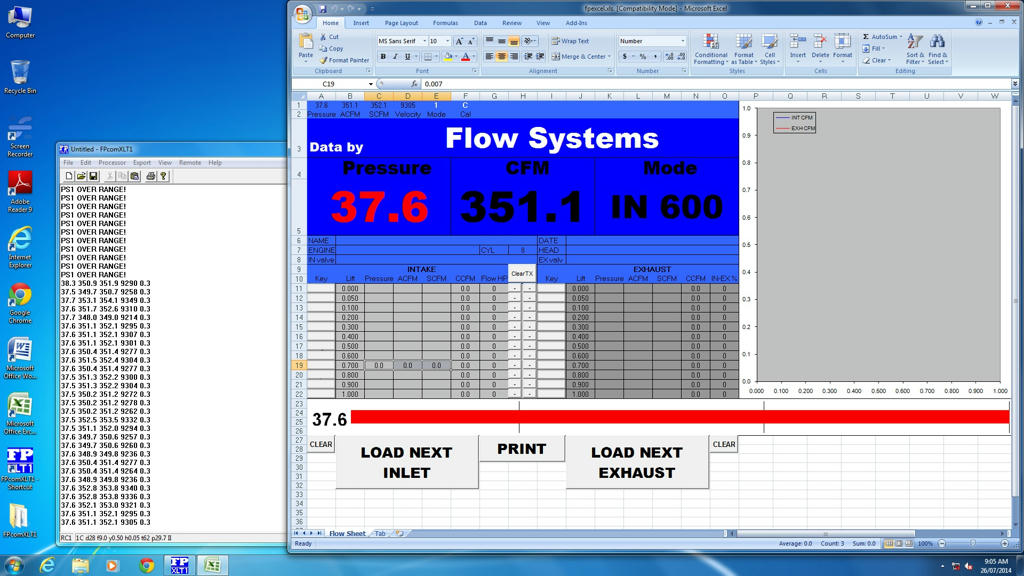

One of the main reasons for having digital measurement and the thing I liked most about it was to NOT have to be frequently changing ranges. The digital units provided that function where the water gauges simply couldn't.

My bench....same thing you're working with but I installed a baffle and raised top section like the SF600 has. I included several SF benches for comparison.

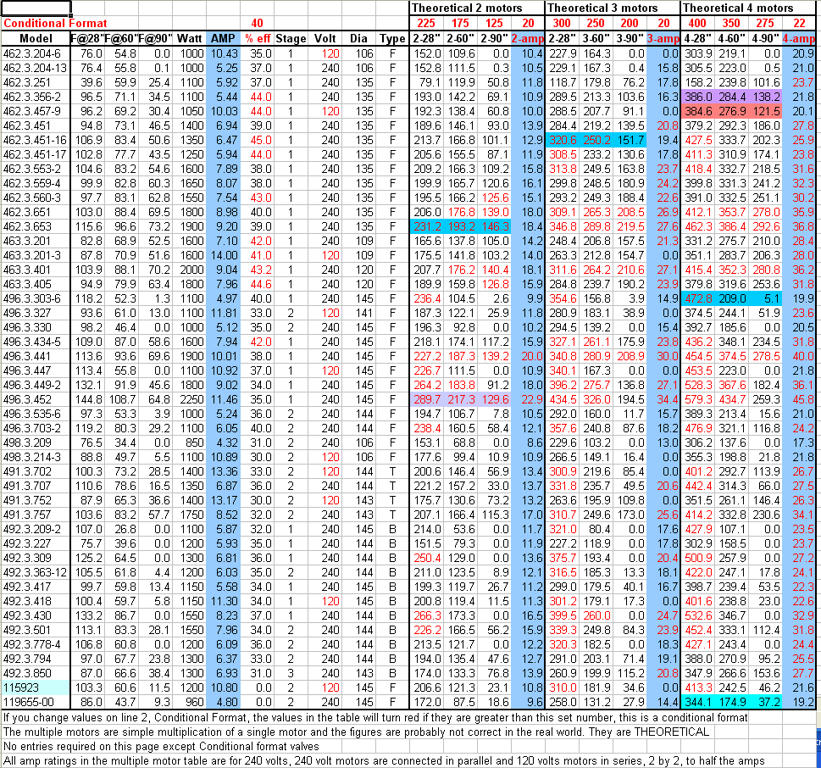

Round Robin Test Resuts Plate 1 CFM % of Ford Plate 2 CFM % of Ford Plate 3 CFM % of Ford Avg of 3 Type Guage

Reher Morrison SF600 Range 4 98.20 100.1% 191.50 98.3% 286.40 96.5% 99.2% Orifice Manom

Reher Morrison SF600 Range 5 99.10 101.0% 199.70 102.5% 296.90 100.0% 101.7% Orifice Manom

Reher Morrison SF600 Range 6 97.10 99.0% 196.70 100.9% 288.10 97.0% 99.9% Orifice Manom

Dave [SF1020] Range 3 99.40 101.3% 190.10 97.5% 282.10 95.0% 99.4% Orifice FlowCom

Larry C 100.50 102.4% 191.50 98.3% 281.00 94.6% 98.4% Orifice FP1

Larry M SF600 w/FP1 98.56 100.4% 193.59 99.3% 289.62 97.5% 99.9% Orifice FP1

Larry M SF600-w/Dwyer Inclined 98.47 100.3% 193.31 99.2% 289.79 97.6% 99.8% Orifice Manom

Dave F. SF600 99.90 101.8% 195.80 100.5% 294.10 99.0% 101.1% Orifice Manom

Curtis SF110 103.50 105.5% 208.50 107.0% 306.30 103.2% 106.2% Orifice Manom

Now.... don't hand me any fluff that the FP1 is inaccurate, outdated, inadequate, etc. etc. etc.

Don't hand me any fluff that the MSD bench design is crap either....

Don't hand me any fluff that you need all sorts of ranges to get the job done....look at Range 5 on the RM bench???

Use the bench you have. Work with the numbers you get. You either gain, don't gain or loose flow when you port heads. The tool you measure it with is arbitrary after you reach a certain point....

Darin Morgan made the comment that he most definitely prefers the SF600 to the SF1020 bench with all it's automated bells and whistles..... Do you think he knows a thing or two about how to use a flowbench for more than looking at CFM numbers???? I personally don't like automatic depression control myself. It masks things you really want to see but hey...that's just me

This isn't to slam the PTS products in any way, shape or form.

That is sweet!